Home

AeriNOx – your trusted partner to reduce NOx and other pollutant emissions from large stationary diesel and natural gas engines. Our highly dependable and cost-competitive emission control products are based on our Selective Catalytic Reduction (NOx Reduction) System. To date we have commissioned over 800 SCR installations throughout the world in engines ranging from 500kW to 20MW.

Our custom-engineered emission control systems reduce NOx and other regulated pollutants as much as 98% from engines operating in demanding environments such as:

- Distributed Power Generation

- Cogeneration Plants (CHP)

- Gas Compression & Transmission

- Oil & Gas Exploration

- Industrial & Chemical Industries

- Marine & Ferry Power

- Greenhouse Fertilization/CO2 Enrichment

Why AeriNOx? Why Now?

Increasingly Stringent Emission Regulations

Owners of diesel and natural gas engines are under constant pressure to reduce emissions. Whether driven by federal regulation or local permitting authorities, lower emissions are an important part of almost every stationary engine project.

Proven Technologies

We’re engineers, and we’ve been in this business for more than five decades. We know the technologies, and we know how they interact with each other to create a reliable and dependable emissions control system.

Emissions Compliance for the long term

Emissions compliance is a legal requirement, not just at your project’s startup, but well into its lifetime. Our experience is based on thousands of successful installations ensuring your emissions control system operates long after it has been commissioned.

Cost-Competitive

We understand emissions control systems are major project expenses. Because we supply hundreds of units per year, we can take advantage of common designs and volume pricing, making the AeriNOx system one of the most cost-competitive in the market.

Federal, State and Local air quality regulations continue to drive down emissions from diesel and natural gas engines.

With the introduction of EPA Tier 4 standards, NOx emissions from diesel engines are reduced by as much as 93%, achievable only with SCR aftertreatment technology. Particulate levels must also decrease by 94%, attained only through the use of a highly efficient diesel particulate filter.

Natural gas engines, while much lower in particulate levels, face equally stringent limits on NOx emissions, particularly in highly populated regions where air quality is compromised. In several of these regions, local regulations are requiring NOx emissions to be less than 10ppm, achieved through the use of SCR. In fact, SCR is defined as the “Best Available Control Technology”, or “BACT”, and must be part of the compliance process.

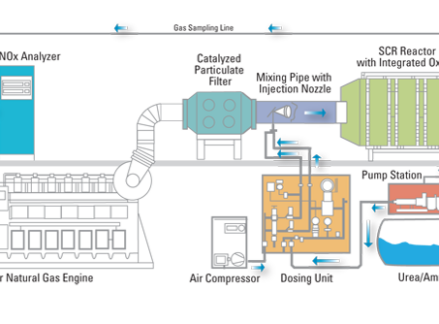

Components

The AeriNOx Difference: Field-Tested SCR Components:

SCR Reactor (with integrated oxicat as an option)

- SCR Catalyst Technology: An effective SCR system begins with the catalyst technology. Our SCR catalyst is a highly efficient ceramic material capable of a wide temperature range (to 500oC / 932oF), high NOx reduction (up to 98%), and long-term stability. The AeriNOx ceramic-based catalyst is extruded into a monolithic honeycomb design that also minimizes backpressure.

- SCR Catalyst Housing: SCR Catalyst Housing: The individual catalyst elements are enclosed in a heat-resistant stainless steel housing, and held in place with a unique locking mechanism to prevent movement during operation.

- SCR Reactor: The catalyst layers are housed in a robust reactor made from high-temperature steel plate engineered for long-term durability. The reactor has separate access panels for each catalyst layer, making installation straightforward and minimizing operational downtime. Our flexible design optimizes the number of catalyst layers for each application.

- Static Mixer: A static mixer ahead of the injection nozzle optimizes the flow conditions to ensure uniform mixing of exhaust and reductant (urea or ammonia solution). This configuration minimizes the injection pipe length providing a more compact design.

- Injection Lance: The AeriNOx injection lance incorporates a two-phase nozzle that, ensures a finely atomized spray pattern and uniform spray distribution. The nozzle is also self-cooled to prevent urea build-up.

Pump Station

- Reductant Pumps: Our systems use pump designs that accurately control the reductant flow from the storage tank to the dosing control system. This eliminates the pulsation phenomenon, enabling very low flow rates necessary for low engine loads.

Dosing Unit

- Dosing Panel: The dosing panel consists of an all-stainless steel design, and comes complete with flowmeter, dosing valve, magnetic valves and shut-off valves mounted on a stainless steel panel.

Control Cabinet with optional NOx Analyzer

- System Control Panel: Each AeriNOx SCR System is managed by a reliable programmable logic controller that has demonstrated decades of field service. The touch panel design allows easy menu-guided parameter inputs. It can also be accessed remotely to monitor operation, or integrated into the facility control system via an optional Profibus data bus communication connection.

- NOx Analyzer: The System Control Panel can be equipped with an optional analysis system that measures NOx directly in the exhaust stream, allowing for highly precise and accurate metering of the reductant. This results in high NOx reduction (as much as 98%) and very little ammonia slip.

About Aerinox

About AeriNOx

AeriNOx is an environmental engineering company supplying cost-competitive and reliable emissions control solutions to the North American stationary engine market.

Our focus is the reduction of NOx emissions from large stationary diesel and natural gas engines through a comprehensive systems approach based on Selective Catalytic Reduction technology, otherwise known as SCR. We then complement our SCR system with the addition of oxidation catalysts or particulate filter technologies to reduce other regulated pollutant emissions, such as carbon monoxide (CO), hydrocarbons (HC), and particulate matter (PM).

From the beginning of every project, we work with you to make sure you meet your emission requirements, including:

- Comparing your engine specifications to the regulations

- Custom designing an emission control system that meets the requirements

- Ensuring the manufacturing process conforms to our exacting quality standards

- Commissioning the system with the AeriNOx Emissions Guarantee

- Providing long-term support through extensive operator training, a well-stocked parts inventory, and on-site maintenance

AeriNOx is a Partnership Leveraging Decades of Experience

AeriNOx is a partnership between DCL International and H+H Umwelt & Industrietechnik. Combining the best of both international companies, AeriNOx leverages over five decades of expertise in the industry, with thousands of successful installations in a wide variety of markets.

DCL is a leader in the design and manufacture of diesel particulate filters and catalytic converters for on and off-highway vehicles, stationary engines, and industrial processes. DCL supplies to world leading engine manufacturers, original equipment manufacturers and the aftermarket retrofit market.

Products

The AeriNOx Systems Approach…

… not just components, but seamless integration into a reliable and durable system that achieves up to 98% NOx reduction.

- Time-Tested Control Panel with Touch-Screen PLC

- Integrated NOx Analyzer for maximum NOx reduction (optional)

- Catalyzed Particulate Filter (optional)

- minimum 85% reduction in particulates (PM)

- up to 95% reduction in CO

- up to 90% reduction in HC

- CARB Verified Level 3+

- Static Mixing Pipe with Two-Phase Injection Nozzle

- Robust SCRReactor with High-Efficiency Catalyst Technology

- up to 90% reduction in NOx

- up to 98% reduction in NOx with NOx Analyzer

- less than 5ppm ammonia slip

- CO and HC reduction with integrated oxicat

- Precision Dosing System for fine metering of urea or ammonia solution

- Pump Station with accurate flow control to low engine loads

- Storage Tank for Urea or Ammonia Solutions (optional)

- Storage Tank Immersion Heater and Heat-traced supply lines for cold ambient temperature operation (optional)

Continue to the Product Components page…

read moreServices

Services: Your Comprehensive Project Partner

From the beginning of every project, we take complete responsibility to make sure you achieve your emission requirements.

Steps we take:

- Compare your engine specifications to the regulations

- Custom design an emission control system that meets the requirements

- Ensure the manufacturing process conforms to our exacting quality standards

- Commission the system with the AeriNOx Emissions Guarantee

- Provide long-term support through extensive operator training, a well-stocked parts inventory, and on-site maintenance

Our Services Portfolio:

- Installation support

- System commissioning

- On-site instruction and training for owners and operators

- On-line emissions monitoring for remote access

- Data logging for reporting to the authorities

- Catalyst inspection and analysis to estimate residual life

- Catalyst replacement schedules for improved budget planning

At AeriNOx, we understand that installing your emission control system is just the beginning of your project. We make sure your system operates as designed with a comprehensive and thorough commissioning process. All product sales include commissioning by experienced field engineers to ensure the system is fully functional.

You need to be compliant. That’s why we guarantee emissions levels.

To give you piece of mind, we offer the AeriNOx Emissions Guarantee as part of our extended service agreement. You tell us the emissions requirements for compliance, and we guarantee the system will meet them. Not just a percent reduction like others in the industry – but the actual stack emission concentrations required by your permit. And not just on day one, but after thousands of hours of operation. We can do this because we are confident in our system, and because of our experience working with hundreds of our systems operating throughout the world in very aggressive environments.

On-site training… becoming comfortable with your system.

Emission control systems are major investments, and we want you to understand what you’re installing, how it works and what it takes to maintain it. We therefore provide on-site training to make sure everyone in your facility is comfortable with the system’s operation and maintenance requirements. This is accomplished with detailed and well-written technical manuals, as well as knowledgeable personnel that will step you through every aspect of your system and its performance.

Parts and service when you need them.

Things wear out, and while we design our emission control systems for long-life, sometimes you need a replacement part.

Compliance for the long term.

Emissions compliance is a legal requirement, not just at the start of your project, but well into its lifetime. Our experience is based on thousands of successful installations ensuring your emissions control system operates long after it has been installed.

AeriNOx Emissions Control Technology

The Technology of Emissions Reduction

NOx Reduction and the Chemistry of SCR…

NOx is a general term referring to Nitrogen Oxide (NO) gas and Nitrogen Dioxide (NO2 ) gas. It forms at the high temperatures of the engine combustion process.

NOx is successfully converted to Nitrogen gas (N2) using Selective Catalytic Reduction, or SCR, the most effective technology available today.

SCR works by promoting a chemical reaction between NOx and ammonia gas (NH3). The ammonia comes from a reductant fluid such as aqueous urea solution, that is injected into the exhaust stream ahead of the SCR catalyst. The heat of the exhaust transforms the reductant fluid to NH3. This chemically reacts with the NO and NO2 at the surfaces of the highly porous catalyst to form nitrogen gas (N2) and water vapor (H2O).

The resulting nitrogen gas and water vapor are harmless to health and the environment, and flow through the system and exit the exhaust stack.

Reducing HC & CO: The Oxidation Catalyst

Carbon Monoxide (CO) and Hydrocarbon (HC) emissions result from incomplete combustion of fuel. Oxidation catalysts, or “oxicats”, are highly effective devices that reduce CO and HC emissions by 90% or more from diesel and lean-burn natural gas engines.

Oxicats consist of a substrate made up of thousands of small channels. Each channel is coated with a highly porous layer containing precious metal catalysts such as platinum or palladium. As exhaust gas travels down the channel, HC and CO react with oxygen within the porous catalyst layer to form carbon dioxide (CO2) and water vapor (H2O). The catalyst can also reduce a small amount of Particulate Matter (PM) by converting it to CO2.

The resulting gases then exit the channels and flow through the rest of the exhaust system.

Eliminating Soot Emissions: Particulate Filter Mechanics…

Particulate emissions (PM) are also a consequence of the combustion process, primarily due to unburned fuel. PM, more commonly known as soot, is removed from the exhaust using a Diesel Particulate Filter, or DPF. The structure of the DPF is similar to that of an Oxicat, except every other channel is blocked with a dense plug.

To remove the soot, raw exhaust enters an open channel at the front of the DPF. The walls of the filter are engineered to be semipermeable, allowing gases to pass through but trapping the soot particles inside.

The DPF contains a thin layer of catalyst that chemically converts the soot particles to harmless carbon dioxide (CO2 ). This allows the filter to function continuously during engine operation. The catalyst also allows the DPF to function as an Oxicat, reducing HC and CO in addition to PM.

Once converted, the gases pass through the filter’s porous walls and into a much cleaner exhaust stream.

Putting it all together into a comprehensive emissions control system…

With AeriNOx technology, achieve compliance with all regulated engine emissions:

NOx: up to 98%

PM: more than 85%

CO: up to 95%

HC: up to 90%

How it works:

- Soot is captured in the particulate filter

HC and CO are converted to harmless water vapor and CO2 - Aqueous urea solution is injected into hot exhaust gas stream

The heat of exhaust converts the urea gas stream solution to ammonia gas and carbon dioxide - NOx reacts with ammonia gas to form Nitrogen (N2) and water vapor

- Any residual CO and HC is removed with the oxidation catalyst

- Clean exhaust exits the stack

read moreThe Reductant: Ammonia, Aqueous Ammonia or Aqueous Urea?

SCR systems work by catalyzing the reduction of NOx with ammonia. The ammonia can be introduced from a variety of sources, including directly as a gas (anhydrous ammonia) or as an aqueous ammonia solution. However, it is more common to use aqueous urea solution as the reductant. A solution made from urea, a common component of agricultural fertilizer, is much safer and easier to handle, and is readily available in several different concentrations and storage capacities.

There are advantages and disadvantages to both ammonia-based and urea-based reductants. The AeriNOx SCR System can be designed to use any of these ammonia sources, so please contact us with your requirements for what works best for you.